Wood, Brick, Stone, Tile & Concrete Floors

The most common material used for flooring in a typical raised residential porch is ordinarily wood or newer composite type materials. Cost, ease of installation, and material choices are 3 big reasons why. Concrete has always been the most used flooring material for ground level porches. Concrete is easy to install and, if installed correctly, will last a lifetime. The big trend over the last several years is to cover concrete with tile, block, stone, or brick. Another less expensive trend is stamped concrete - which will resemble stone, block, etc. And yet another trend is to build a free standing roof structure and use concrete pavers for the floor. SNAPP® Screen installation into all these situations is very simple but each is managed slightly different.

The most common material used for flooring in a typical raised residential porch is ordinarily wood or newer composite type materials. Cost, ease of installation, and material choices are 3 big reasons why. Concrete has always been the most used flooring material for ground level porches. Concrete is easy to install and, if installed correctly, will last a lifetime. The big trend over the last several years is to cover concrete with tile, block, stone, or brick. Another less expensive trend is stamped concrete - which will resemble stone, block, etc. And yet another trend is to build a free standing roof structure and use concrete pavers for the floor. SNAPP® Screen installation into all these situations is very simple but each is managed slightly different.

Wood or Composite Flooring - Direct Installation

The three porches shown below all have wood or composite flooring. In each installation, the base extrusions were installed directly to the flooring material. This is most common installation method used for base extrusion installations.

Wood or Composite Flooring

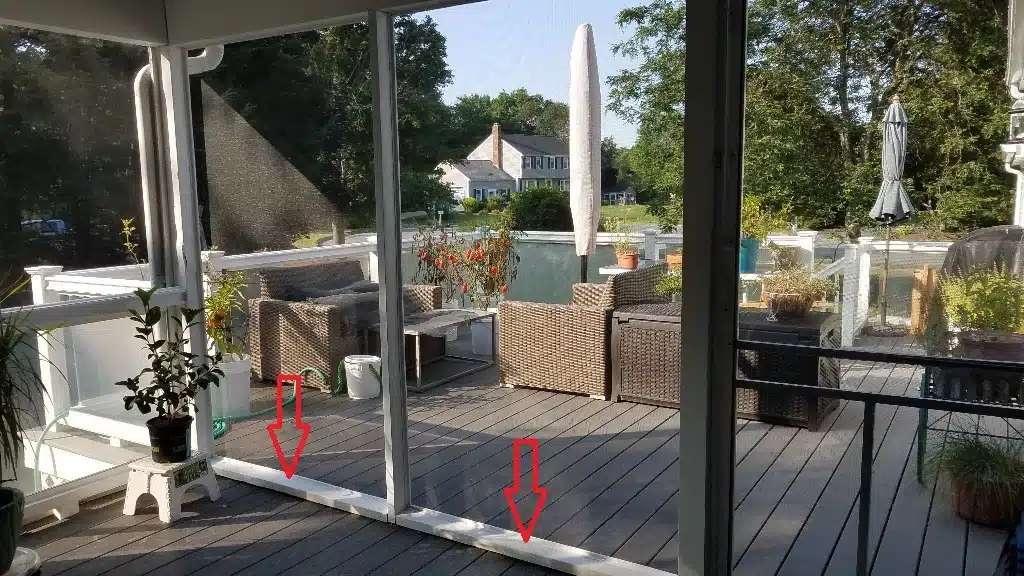

The three porches shown below also all have wood or composite flooring. In each of these installations, a “starter strip” was installed first, then the base extrusion was installed directly on top. This is also a very common installation method used. There is no “rule” that requires this in these installations – in most cases they are included simply for ease of installation and/or customer preference that screen be off the floor.

* A "starter strip" or "spacer" is either a wood or PVC material used to add room in between the extrusion and the floor, a column, wall, etc. These are sized as needed and are not required in all installations, they are most often used on concrete or stone floors as well as stone or brick columns. Benefit of a starter strip, besides added work room, is that the SNAPP® screen extrusion can be installed using standard hardware (for appearance) and any masonry hardware used to mount he starter strip is hidden underneath.

Brick, Stone, Tile & Concrete Floors

The use of a "starter strip" or "spacer” is the preferred method of installation whenever installing onto brick, stone, tile or concrete. This practice will allow a minimum number of masonry anchors be used as well as the ability to hide the anchors under the extrusion during installation. This will also provide a smooth installation surface to work with since most brick and stone floors are far from perfect.

While there will always be installations where smooth tile or concrete are be present, it is still almost always more desirable to use a "starter strip". (Keep in mind the extrusions require installation screws every foot. A direct install into tile or cement would then require a masonry anchor or Tap Con every foot also)

In cases where the floor is very uneven and natural space is present under the "starter strip", leave the smallest spaces for water to weep and fill in any large spaces using only soft solid roll foam, lightly tucking in a minimal amount with a screwdriver or putty knife. (do not use spray foam or caulk)

Shown below: Brick floor installation (left), Blue stone floor installation (center), Blue stone & brick floor installation (right).

Concrete Paver Floors

Concrete paver floors have become a trend over the last few years. Generally, a free standing, properly footed, roof structure is constructed, and pavers are used for the floor. (these are pretty much free-standing gazebos) Some of these floor patterns are simply stunning. Unfortunately, nothing can be anchored to the “floor” since the pavers can move over time.

The way you get around this is to place a starter strip along the base (sitting on the “floor”) and secured to the vertical roof supports. If the roof supports are close (36” to 48”) apart, you can use a standard 2x4 (with the largest side facing outward / inward). Openings larger than 48” will require larger dimensional lumber. Best practice is to modify all openings to 60” or less and use standard 4x4 for base strip.

Standard Notes For All Installations

• It is recommended that neoprene or plastic washers (+/- 1/8”) be used to create a weep space for water drainage between the floor and the extrusion or "starter strip" (whichever is touching the floor of the stricture). 2 or 3 are fine. These are only intended to create a tiny gap to allow water to weep out. They do not need to be around installation screws or secured in place.

• Powder coated aluminum can be mounted directly to concrete and pressure treated materials. For added protection, we recommend a bond breaker be applied between aluminum extrusions and the concrete / PT material. Simply run standard electrical tape on the back side of all aluminum extrusions to break the bond between the mounting surface and extrusion.