Custom Finishes & Track Painting

It is possible to apply custom finishes to both our extruded aluminum and extruded PVC SNAPP® screen Track. We do not apply custom finishes, but the directions below will assist and guide you in the right direction.

It is possible to apply custom finishes to both our extruded aluminum and extruded PVC SNAPP® screen Track. We do not apply custom finishes, but the directions below will assist and guide you in the right direction.

When applying a custom finish to our aluminum track, unfinished (“Mill”) would be the product to use.

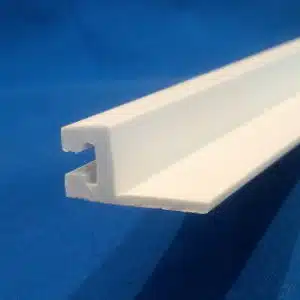

When applying a top coat to our PVC track, stock white would be the product to use.

Aluminum Finishing

Professional finish applications: Search your local area for powder coaters, anodizers or painters depending upon the finish desired. Be sure to also check with local auto body shops. These are a great resource and they’ll have no problem preparing the metal and mixing custom colors.

Most commercial applicators will have a minimum volume requirement or a minimum run charge. In all cases, your cost will depend upon the volume of material being finished and the actual finish being applied.

Home finish applications: Aluminum does not take paint as well as other materials, but it’s not difficult to paint yourself if you follow some simple steps.

1) Clean tracks of all dirt, grease, oil, or anything else that could interfere with the paint application and adherence. Mill aluminum is dirty to begin with and all aluminum has a naturally occurring thin protective coating that must be removed for proper adhesion. We find red scotch brite and a good quality degreaser will work fine. Do not use heavy steel wool or anything that would produce gouges in the metal ... gouges will show after painting. MEK is a commercial degreaser that will clean the metal very well.

2) Prime the prepared metal using aluminum etching primer. This primer is easily available at any good automotive or home center. Follow all directions provided by the paint manufacturer.

3) Once the primer has dried, you can use almost any kind of paint to finish coat. We would recommend you use the same brand finish paint as the primer used. Always apply several small coats as per the paint manufacturer’s instructions and do not over apply paint into the spline channel .... you can’t see inside once screened and overpainting can cause retention failure.

Normally all extrusions would be finished prior and cut to size during installation. If you plan to precut all extrusions then apply finish, be sure to slightly undercut all lengths to account for added paint finish on extrusion ends. Do not install raw extrusions and paint in place.

PVC Finishing

PVC is pretty simple to top coat but because it’s a plastic, that can flex or move, you can only use 100% acrylic latex, or 100% acrylic latex with a urethane additive. Sherwin Williams, PPG and Benjamin Moore all offer paint specific for PVC and each will provide superior durability and flexibility. The use of other paints or coverings will end in peeling and cracking.

Use our white track and paint only with warm to light colors - dark colors can cause heat absorption beyond the product design and damage the extrusion.

While the track can be sprayed using an airless sprayer, it is generally best to install the extrusions first and brush finish in place. In each instance, do not pack paint into the spline channel ... you can’t see inside once screened and overpainting can cause retention failure.

Final Notes:

Take your time – cutting corners during the finishing process will ensure paint failure.

You can also seek out additional assistance / advise from any professional paint store or supply house. Be sure to read, understand and follow all product directions including all safety requirements & warnings for the products being used.